Sediment Backwash Filters

- Got rust, sediment or particles in water?

- Self-cleaning backwash systems have got you covered.

- Remove dirt, rust and sediment down to 5 microns!

- Unlike filter-cartridge systems, these systems will not restrict flow or pressure.

Overview

- All sediment backwash systems include filter media, tank, backwash control valve, bypass valve, and free shipping!

- Easy to service: little or no maintenance.

- Proven technology used over decades.

- No chemicals or salt required.

- Timed backwashes based on flow and/or day of the week. Choose between rugged long lasting 7500 ceramic disc valve series, 5900 series with blue tooth and app, or manual backwash type.

Turbidex: The Filter Media

The Turbidex filter material used in these systems is capable of removing sediment and particles down to 5 to 10 microns in size, leaving your water clear of rust and sediment.

Turbidex is a high purity, low sodium, natural, zeolite mineral (14 x 40 mesh) that has an ANSI/NSF Standard 61 listing. The material is mined, crushed, dried, and double-screen sized to produce a high-quality filter media that has a high throughput capacity at low differential pressure.

Compared to filter sand and some other filtering media, you can retain much more water flow with less pressure loss using Turbidex. The media has surface micro-mineral projections (with 0.25 to 10 µm spacing that effectively traps suspended solids. This, along with the high surface area, make Turbidex an ideal water filtration media.

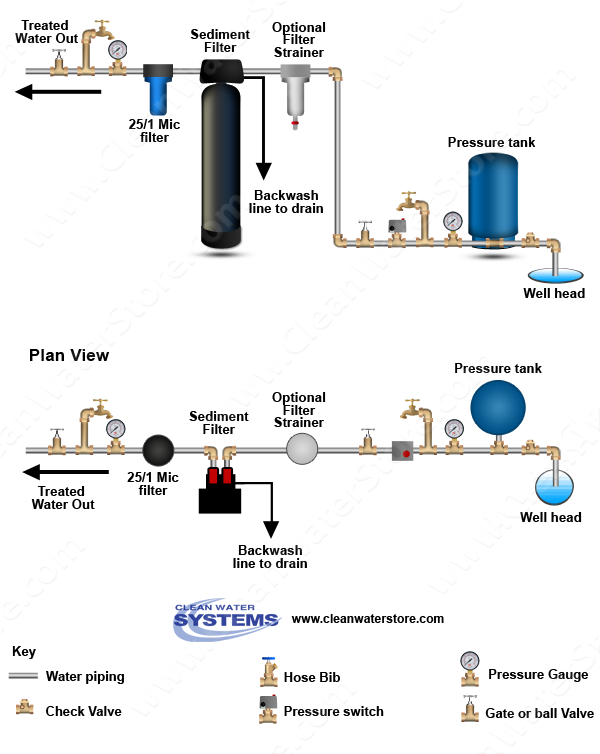

Easy Installation

Quick to install by any plumber or any person familiar with basic plumbing! Connect filter system to piping after your pressure tank using bypass connectors (included at no extra charge) to enjoy sediment-free water.

Frequently Asked Questions

A. All backwashing filter systems (such iron filters, softeners, any type of backwash system) must be after the pressure tank because when the backwashing filter goes into a backwash, say at 2am on a given night, there must be pressurized water entering the inlet to the sediment filter, in order for it to backwash properly.

If the pressure tank were after the system, and the filter system went into a backwash, the well would not turn on because there is a check valve before the pressure tank to prevent the water from being discharged back into the well, and the pressure switch would not register that the pressure had dropped and the pump must turn on. If the check valve was down the well, or on the other side of the sediment filter, say on the inlet to sediment, when the sediment filter went into a backwash, the water would enter the sediment filter through the outlet on the sediment, not the inlet, causing it not to backwash and causing other problems.

The pressure tanks have the in and out pipe (typically one pipe on captive-air pressure tank) on the direct bottom of the pressure tank, so usually no sediment will build-up in the tank. But in any case, there is no way to use a backwashing filter before the pressure tank. Also, say you wanted to use a cartridge filter instead of a backwashing filter system, and you placed a cartridge type filter before the pressure tank. After a while if this filter became plugged up, your well would not be able to shut off properly because the pressure on the inlet side of the filter from the well is much higher than the pressure tank pressure. This will cause the pressure switch to rapidly turn on and off and eventually cause damage to the well pump motor.

Generally it is NOT a good idea to put any type of flow restriction such as a filter cartridge or backwash filter before your pressure tank and it is not necessary in any case because modern pressure tanks are lined with a special coating to prevent corrosion.