7 Warning Signs Your Water Well Is In Trouble

Learn to troubleshoot water well problems quickly!

While most well owners don't experience well water problems frequently, it can be frustrating if it happens to you.

The typical modern residential well is a fantastic resource and can produce many years of excellent water with minimal servicing. Most wells can operate for many years without maintenance.

However, homeowners sometimes don't realize that their water well requires service and routine maintenance until it is too late.

Common questions about well water problems include things like I have bad pressure tank symptoms; how can I fix this? Why is my well water sputtering? I need help with well pressure tank troubleshooting. How does a well system work? If you have poor water pressure, you may be able to troubleshoot it yourself.

The good news is that there are some tell-tale signs to look for that will alert you to water well problems and well pressure tank problems.

There are some simple steps that you can take to troubleshoot water well problems.

How A Typical Well Pump System Works

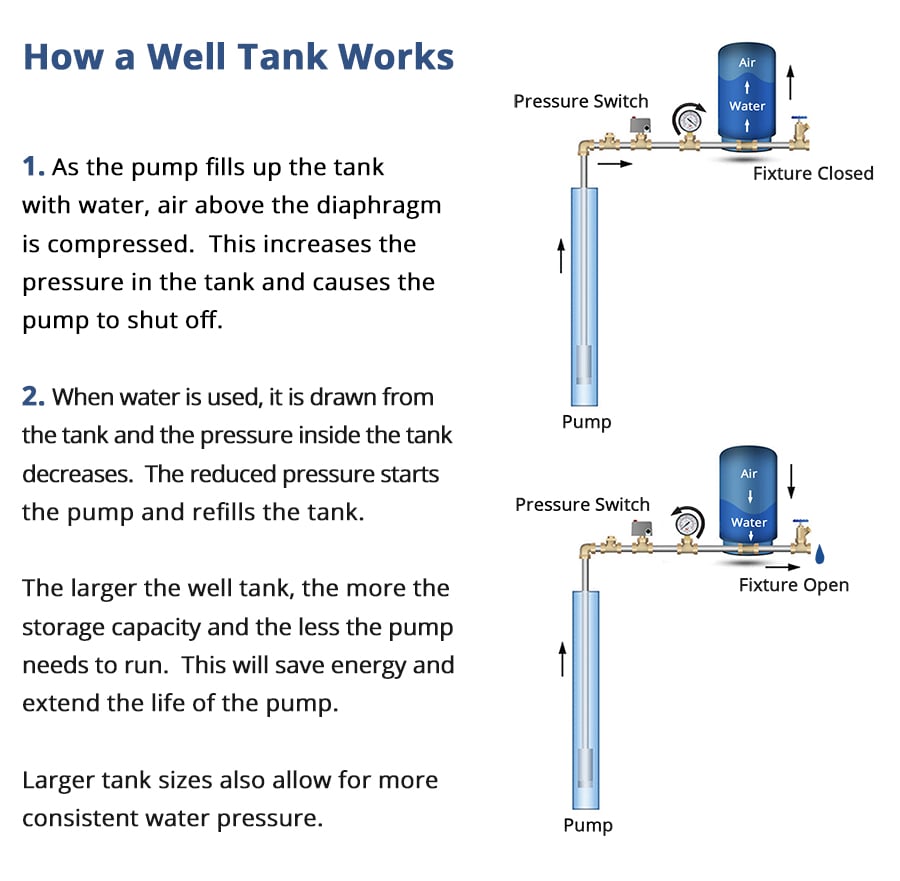

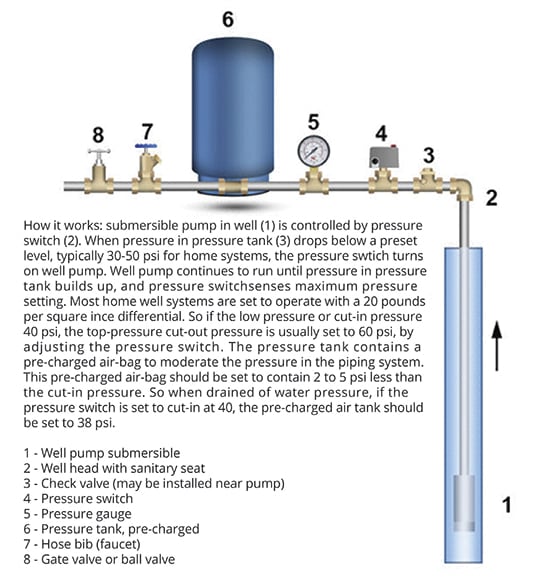

A typical residential water well usually has a submersible pump and one or more pressure tanks that pump water directly to the house.

Some wells have pumps called “jet pumps” located on the surface or top of the well. Most well pumps are used in conjunction with a pressure tank.

The well water pump system aims to maintain a constant supply of pressurized water in the house and piping system. To maintain the water pressure, the well pump is switched on and off with a pressure switch.

This usually means the pump is turned on when the pressure switch senses the pressure is at a low point (the “cut-in” point) and off at a pre-set high-pressure point (the “cut-off” point). In some systems, there is no simple on-and-off pressure switch. These systems have a pressure sensor that works with a controller to allow the pump to pump more or less in a gradual method called a “constant pressure” system.

This system uses a variable-speed pump, which allows the pump motor to spin faster or slower and pump water faster or slower based on the pressure sensor. These are becoming increasingly popular, but the most common is the simple off-and-on pump system, which uses a simple pressure switch.

The 7 warning signs associated with water well problems:

1. The well is pumping air, and well yield is reduced (a low producing well)

2. The well is pumping sand or large amounts of sediment

3. Water pressure is low (pressure tank symptoms)

4. The power bill has skyrocketed

5. Water quality has changed

6. Dissolved gasses or bubbles and air in well water

7. The pressure switch and pump continuously cycle on and off (short-cycling).

1. The Well is Pumping Air

Certain water well problems show up after some years. A good example is when you turn on your kitchen faucet and out blasts a mixture of air and water. The worst-case scenario is that your water table has dropped to the point at or below the well pump, and the pump is drawing in the air sometime during the pump cycle.

Another cause is when the well pump drop pipe (the pipe that connects the pump to the top of the well and the water system) is broken. Drop pipes are either iron pipe, plastic PVC, or poly pipe.

They may become broken/corroded and develop cracks or even, in some instances, break apart, allowing air to be sucked in. This kind of problem needs to be looked into and repaired by a skilled well or pump company.

2. The Well is Pumping Sand or large amounts of sediment

If your water well suddenly starts to pump sand, this is often a sign that the well is silting in or filling with sand and silt. Typically, the well pump is installed so it is at least 10 – 20 feet above the bottom of the well.

When the pump turns on, the water level in the well can drop to a lower level. If the pump is down near the bottom of the well, sand and sediment can be sucked in.

Other causes for sand in water can be that the well screen has degraded and allows sand or sediment in from the gravel pack around the well screen.

Sand can quickly wear out the pump valves and fill up the bottom of the well with sand. In any case, the sudden presence of sand is not a good sign, and troubleshooting is required.

Sand can be removed from the water before the pressure tank or storage tank using a sand and sediment trapper or a 60 mesh filter screen with an automatic purge valve.

3. Low Water Pressure

If you are experiencing no water from the well, there can be many low water pressure causes, including a failing well pump, stuck check valve, partially closed or bad gate/ball valve, and leaking/failing pressure tank. In some cases, iron bacteria clog up the pipe nipple leading to the pressure switch causing the pressure switch to sense pressure incorrectly.

If the well water tests high in iron bacteria, your pump and/or well screen may become clogged with iron bacteria. Cleaning the well with a special solution designed to remove iron bacteria, slime, and scale can often restore the well to a better condition.

The pressure is often set to turn on at 30 PSI and off at 50 PSI in some well systems. For today’s homes and appliances, this pressure can be too low. Often it is possible to raise the pressure, so the pump turns on at 40 to 50 PSI and off at 60 to 70 PSI, providing adequate water pressure in the home.

The pressure switch can often be adjusted to accommodate this higher pressure, assuming the well pump and well can operate without difficulty at the higher pressure. If the pressure switch is adjusted, the air pressure inside the tank must be adjusted.

4. The Electricity Bill has Skyrocketed

When a pump wears out or becomes blocked with sand, silt, or iron bacteria, it needs to work much harder than if it were in good shape.

This overworking can result in an increasingly higher power cost. Another common cause of a high power bill is when the check valve in the well goes bad, causing “short cycling”. This allows water from the pressure tank to stream back down into the well.

This enables water from your pressure tank to flow back into the well, reducing pressure and signals to the pressure switch to turn the pump on again and pressurize the pressure tank.

This on and off-cycle may occur every few minutes and essentially allow the well pump to run practically 24 hours a day, causing a high power bill.

5. Water Quality has Changed

If you notice a sudden change in water quality, this can indicate that something has happened to your well shaft, casing, pump, or drop pipe. Sudden problems such as a large amount of sand, sediment, odors, or color can indicate that surface water has penetrated or leaked into your well.

The best thing to do if your well water quality changes sharply over a few days is to get your water tested. If you notice a big drop in water pressure or see large amounts of sand or grit, you should reach out to a well water professional such as your local well driller or licensed pump contractor.

If you don't have a local well contractor, a good place to start is, a National Groundwater Association service.

6. Dissolved gasses or bubbles in the water

Is the air dissolved in the water, or is it sputtering out of the tap in big bursts?

A professional well or pump contractor must investigate and repair these water well or pump problems.

The water level is fine in some cases, and there aren't any cracked pipes or fittings. Some groundwater tables do contain contaminants and various types of gas. These gases may be dissolved within the water, yet later come out of the solution and trigger water to spurt or sputter out of the tap.

These gases may be carbon dioxide, methane, hydrogen sulfide, or other gases. Such gases can be harmful and cause significant safety and health problems. If this is an ongoing problem, the well can be treated to eliminate these gases using aeration and degassing systems.

7. Pressure Switch and Pump Continuously Cycles On and Off

A leak in the home can cause this water well problem, so the well pump continuously runs.

It can also be due to corrosion of the water well casing, liner, or screen, causing holes. Holes can allow water of undesirable quality to enter the well. Look for leaking toilet flush valves, reverse osmosis systems, iron filters, and other backwashing filter systems that may malfunction.

Also known as ‘short cycling,” this can cause your well pump to wear out prematurely and your electric bill to go up significantly. A common cause is a failed check valve. The check valve or foot valve prevents either the pump or well pressure tank (sometimes referred to as a bladder tank) from sending water back into the well after it has built up with water pressure.

If the valve fails, the pump starts, water streams down the well, and the pressure switch turns the pump on again. This on and off-cycle may occur every few minutes and essentially allow the well pump to run practically 24 hours a day, causing a high power bill. Replace the check valve, and the problem is solved.

Another widespread issue is the pressure tank losing its captive air pressure. This is easy to check.

Turn off power to the well pump and run water after the pressure tank or in the house until there is no water pressure left. Using a tire pressure gauge check the Schrader valve on top of the pressure tank. It should be 2 PSI less than the cut-in or lower pressure. If your well turns on at 30 and off at 50 PSI, it should have 28 PSI in it.

The 7 Top Water Well Problems

What to check for your well water problems:

What to check for your well water problems:

-

Changes in water quality are often coupled with the sudden appearance of sediment in the water such or air in water lines.

-

Failure of the annulus or casing seal

-

Iron bacteria or sulfate-reducing bacteria (biofouling)

-

Change in water quality such as color, odor (e.g., rotten egg), or taste. Check inside of the toilet tank for slime buildup and inspect the pump.

-

Contamination from human-made sources

-

Changes in water quality as indicated by color, odor, or taste. Compare results from regular water analyses for changes.

-

Limited aquifer extent/Reduced aquifer recharge

-

Increase in constituents such as hardness, iron, manganese, and sulfate. Compare results from original water analyses for changes. Taste and color changes in the water may also occur.

How to correct well water problems:

-

If your well pump is not working consult with a licensed drilling contractor about the possible repair. Alternate construction materials may be required. See wellowner.org for help.

-

Calculate the Langelier Saturation Index to determine the water’s corrosion potential.

-

Identify and remove the contamination source.

-

Have water analyzed to ensure it is safe to drink

-

Install treatment systems to remove sand either in a well or before the pressure tank.

-

To remove excess gasses in the water, install aeration and degassing system.

-

Shock chlorinate well water and piping system.

How to do well pressure tank troubleshooting?

1. Turn off the power to the well pump.

2. Relieve pressure in pipes by opening the hose bib or faucet.

3. Check the air pressure in the tank by using a tire pressure gauge on the pressure tank's air valve.

4. Add air to the pressure tank until air pressure is 2 PSI less than the cut-in or lower pressure on your pressure switch.

5. Turn on the well pump.

6. Open the faucet or hose bib and run the water until clear.

What are some bad pressure tank symptoms?

1. If you check the air pressure on the air valve on top of your pressure tank, and water comes out (pressure tank bladder is bad)

2. Your pressure switch turns on and off rapidly, indicating the pressure tank needs air or is bad.

3. Your pressure tank has excessive rust or corrosion on the outside.

4. Leaking pressure tank. If you have a leaking pressure tank, it will most likely need to be replaced.

Why is my pressure tank losing pressure?

1. If you have a standard captive air bladder type pressure tank, this is almost always an indication the bladder inside the tank has ruptured. Generally, these are not serviceable, and the pressure tank must be replaced.

2. In some cases, the air valve on the top of the tank can leak and might need to be serviced.

How your well pressure tank works

What to check for your well water problems:

What to check for your well water problems: