Calcite Neutralizer

What is a Calcite Neutralizer?

A neutralizing filter, specifically a calcite neutralizer, is a water treatment system designed to neutralize acidic water by raising its pH level. It utilizes calcite, a naturally occurring mineral composed of calcium carbonate, to correct the pH of acidic waters. When acidic water flows through the calcite media, the calcium carbonate neutralizes the water, effectively reducing its acidity. This process is crucial for protecting plumbing systems, appliances, and overall water quality from the corrosive effects of acidic water. Calcite neutralizers are widely used in both residential and commercial applications, providing a reliable solution for maintaining balanced water chemistry.

How Calcite Neutralizers Work

Calcite neutralizers operate by slowly dissolving calcite media in acidic water, which in turn increases the water’s pH level. The process of neutralizing acidic water with calcite can increase hardness. The calcite media, typically placed in a backwashing filter, interacts with the acidic water as it flows through the system. As the water passes through the calcite, the calcium carbonate dissolves, releasing calcium and magnesium ions that neutralize the acidity. This process results in a non-corrosive effluent that is safe for typical plumbing systems. To ensure continuous effectiveness, the calcite media must be periodically replenished, maintaining the system’s ability to neutralize acidic water efficiently. Calcite neutralizers can also reduce the potential leaching of copper from plumbing systems.

Understanding the Difference Between Up-Flow and Down-Flow Calcite Neutralizers: How Calcite's Calcium Carbonate Neutralizes

Down-Flow neutralizers have backwashing control valves and the calcite media is backwashed and rinsed periodically. Maintaining high service rates is crucial for optimal performance and effective acid correction.

In a standard downflow neutralizer, the water enters the top of the tank, flows down through the media, and up the distributor tube. Service flow rates can influence the effectiveness of pH neutralization in downflow systems and need to be adjusted according to the mix of Calcite and Corosex media for optimal performance.

The down-flow type neutralizer removes sediment and can be backwashed, which cleans and reclassifies the calcite, preventing channeling. During backwash, the water flow is reversed, and water flows down the distributor tube and up through the media, lifting and expanding the calcite media. During the backwash, the calcite is cleaned by the action of the water flowing through it.

Up-Flow Neutralizers Do Not Use or Need a Backwash Control Valve: Understanding Backwash Bed Expansion

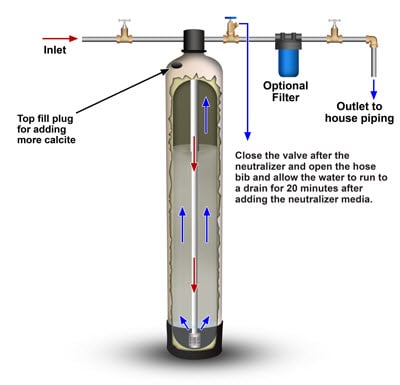

In an upflow neutralizer, water always flows down the distributor tube and up through the calcite media. Upflow neutralizers have no backwash control valve and are not backwashed because the water is always flowing up through the calcite, so there is no need for a backwash. This type works well in some applications and prevents the need for any backwash drain connection. High-quality material is used in upflow neutralizers to ensure safety and reliability for potable water contact.

Upflow neutralizer. An optional filter is often used after upflow neutralizers to prevent calcite from accidentally rinsing into the home.

However, the upflow types often have problems with channeling, which is where the water can flow up around the calcite, and eventually, the calcite hardens and partially solidifies. If the water is very clean and low in sediment and the water is low in hardness minerals, an upflow type can work fine. For example, these types of neutralizers are ideal for whole-house reverse osmosis systems (which purify and remove almost all minerals and salts from the water) to add some minerals back into the purified water before it enters copper piping. Upflow neutralizers are also ideal for naturally soft water and water low in hardness minerals. Screened white marble media is often used in upflow neutralizers to neutralize acidic pH levels and reduce harmful metal leaching.

Using a backwash type is more convenient and effective for most residential applications, however, as the calcite is kept clean and re-classified. This allows the calcite to dissolve evenly and makes it easier to maintain. Additional calcite can be added on top of the calcite in the neutralizer and then backwashed.

Benefits of Using a Calcite Neutralizer

Using a calcite neutralizer offers several significant benefits:

- Neutralization of Acidic Water: Calcite neutralizers effectively raise the pH level of acidic water, making it safer for household and commercial use.

- Protection of Plumbing Systems: Calcite neutralizers help prevent corrosion damage to pipes and appliances by neutralizing acidic water.

- Improved Water Quality: Calcite neutralizers can remove acidic ions, enhancing the taste and odor of water and resulting in better overall water quality.

- Cost-Effective Solution: Calcite neutralizers are a cost-effective solution for neutralizing acidic water compared to other treatment methods.

- Energy-Efficient: Calcite neutralizers require minimal maintenance and are energy-efficient, making them a practical choice for long-term use.

- Prevention of Metal Leaching: Calcite neutralizers help prevent the leaching of copper, lead, and other metals from plumbing systems, reducing corrosion and improving water quality.

- Increased Water Hardness: While calcite neutralizers improve water quality, they will increase water hardness, which may necessitate the use of a water softener.

Indications for Using a Calcite Neutralizer

A calcite neutralizer is an essential tool for anyone dealing with acidic water. Here are some key indications that you might need one:

- Acidic Water: If your water has a pH level below 7, it is considered acidic. Acidic water can cause a range of issues, from an unpleasant taste to potential health risks. A calcite neutralizer can effectively raise the pH level, making the water safer and more palatable.

- Corrosion Damage: Acidic water can corrode pipes, fittings, and appliances, leading to costly repairs and replacements. A calcite neutralizer helps protect your plumbing system from corrosion damage by neutralizing the acidity.

- Leaching of Heavy Metals: Acidic water can leach heavy metals like lead, copper, and other metals from pipes and fittings, posing a significant health risk. A calcite neutralizer can prevent the leaching of these harmful metals, ensuring safer drinking water.

- Low pH Waters: A calcite neutralizer is an effective solution for households and businesses with low pH waters. It neutralizes the acidity, bringing the water to a more balanced pH level.

- Well Water: Well water often contains carbonic acid, making it acidic. A calcite neutralizer can neutralize this acidity, making well water safer for consumption and use.

Choosing the Right Calcite Neutralizer

Selecting the right calcite neutralizer for your needs involves several important considerations:

- Determine Your Water’s pH Level: Before choosing a calcite neutralizer, test your water's pH level. This will help you select a system that can effectively neutralize your water.

- Consider the Flow Rate: Ensure the calcite neutralizer you choose can handle your household’s or business’s water flow rate. This ensures effective neutralization and consistent water quality.

- Look for NSF Certification: Choose a calcite neutralizer that is NSF certified. This certification guarantees the system’s quality and effectiveness, giving you peace of mind.

- Check the System’s Maintenance Requirements: Some calcite neutralizers require periodic backwashing, while others need regular replenishment of calcite media. Choose a system that fits your maintenance schedule and preferences.

- Consider the Cost: Calcite neutralizers vary in price. Consider your budget and choose a system that offers the best value for your money without compromising on quality.

Calcite Media vs. Acid Neutralizer

When it comes to neutralizing acidic water, both calcite media and acid neutralizers are effective, but they have distinct differences:

- Calcite Media: Calcite media is a naturally occurring calcium carbonate that slowly dissolves in acidic water, raising its pH level. It is a simple and effective solution for mildly acidic water.

- Acid Neutralizer: An acid neutralizer uses a chemical reaction to neutralize acidic water. It can be more effective than calcite media in extremely acidic water, providing controlled pH correction.

- Controlled pH Correction: Acid neutralizers offer precise pH control, which can be beneficial in situations where exact pH levels are required. This makes them suitable for specific industrial applications.

- Self-Limiting Property: Calcite media has a self-limiting property, meaning it will only correct the pH to a non-corrosive equilibrium. This prevents over-correction and ensures the water remains safe for typical plumbing systems.

Adding Calcite to Your Water Treatment System

Incorporating calcite into your water treatment system is a straightforward process that can significantly improve water quality:

- Determine the Correct Dosage: Calculate the correct amount of calcite needed to neutralize your water’s pH level. This ensures effective treatment without over-correction.

- Choose the Right Calcite Media: Select high-quality calcite media that is NSF certified. This guarantees the media’s effectiveness and safety for your water treatment system.

- Add Calcite to the System: Follow the manufacturer’s instructions to add the calcite media to your system. Proper installation is crucial for optimal performance.

- Monitor the pH Level: Regularly check the pH level of your water to ensure the calcite is effectively neutralizing it. Adjust the dosage as needed to maintain the desired pH range.

Maintenance and Upkeep of a Calcite Neutralizer

Regular maintenance and upkeep are essential to ensure the optimal performance of a calcite neutralizer. This includes:

- Periodic Backwashing: The calcite media should be backwashed regularly to remove debris or sediment that may have accumulated, ensuring its effectiveness.

- Replenishing Calcite Media: The calcite media should be periodically replenished to maintain its effectiveness in neutralizing acidic water.

- Monitoring pH Levels: Regular monitoring of pH levels is necessary to ensure that the calcite neutralizer is functioning correctly and maintaining the desired pH range.

- Cleaning the Filter: The filter should be cleaned regularly to prevent clogging and ensure optimal performance.

By following these maintenance and upkeep procedures, a calcite neutralizer can effectively and long-lastingly neutralize acidic water, protecting your plumbing system and improving water quality. After the neutralizing process, a water softener may become necessary to manage increased hardness.

Factors Affecting Calcite Neutralizer Performance

Several factors can influence the performance of a calcite neutralizer:

- Water Chemistry: The specific chemistry of the treated water can impact the calcite neutralizer's effectiveness. Factors like mineral content and contaminants play a role.

- Flow Rate: The flow rate of water through the system affects the calcite neutralizer's performance. Ensure the system is designed to handle your water flow rate for optimal results.

- pH Level: The initial pH level of the water being treated is crucial. The more acidic the water, the more calcite media may be required to achieve the desired pH balance.

- Maintenance: Regular maintenance, such as periodic backwashing and replenishing calcite media, is essential to keep the system functioning effectively. Neglecting maintenance can reduce the neutralizer’s performance.

- Water Hardness: Water hardness can affect the performance of the calcite neutralizer. In some cases, a water softener may become necessary to complement the neutralizer and ensure optimal water quality.

Looking for water treatment solutions you can trust?

Visit Clean Water Store to explore expert resources, high-quality products, and personalized support for your home water needs. We're here to help you enjoy cleaner, safer water every day.