Ozone Water Treatment For Well Water: The 6 Things You Need to Know First

Podcast: Play in new window | Download

Subscribe: RSS

Why use ozone water treatment for your well water?

#1: Ozone is a powerful disinfectant:

Ozone water treatment can rapidly disinfect your well water and kill bacteria and viruses, but unlike chlorine does not leave a chemical chlorine residual.

#2: When used with filtration, it removes iron, manganese, and sulfur odor:

When combined with filtration, the oxidizing properties of ozone will eliminate iron, manganese, and sulfur and reduce or eliminate taste and odor problems.

#3: Ozone is automatic and doesn't require additional chemicals:

Ozone is a gas that is generated by an ozone generator at your site and injected into your water.

#4: Sizing is critical:

Ozone generators need to be sized to fit the application. They produce ozone in grams per hour, depending on your well water flow rate and chemistry.

#5: Decide on ultraviolet (“UV”) light ozone water treatment or corona-discharge type:

While UV light can produce low levels of ozone, it works best for removing slight odors and should not be used for disinfection. Corona discharge uses electricity inside a ceramic or glass cell or stainless steel plate chamber to produce ozone. It works better with dry air, and there are cartridges that will produce dry air and help the generator produce high levels of ozone.

#6: Inject ozone under pressure for best results:

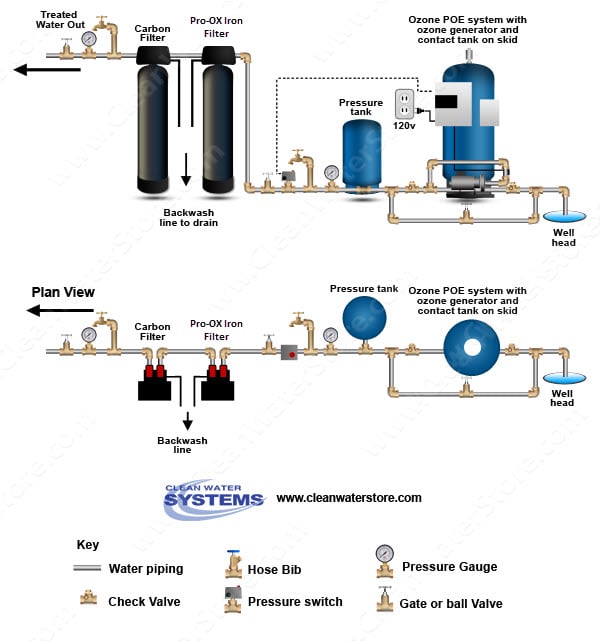

Ozone can be bubbled into the water in open storage tanks or low-pressure vessels, but most of the ozone does not get transferred into the water. For optimum ozone transfer into water, it is much better to draw in the ozone with a venturi into a contact tank under 40 – 50 PSI of pressure.

Ozone Systems Are Widely Used for Bottling Water and Water Purification Worldwide

Ozone has been used for over 100 years to treat water for cities, bottling water plants, and other commercial and industrial processes. Home systems have been available for some years and have improved in quality and design.

If you have iron, manganese, odor, AND bacteria, ozone combined with proper filtration can work great and last for many years.

Ozone water treatment oxidizes iron, manganese, and sulfur in your well water to form insoluble metal oxides or elemental sulfur. These insoluble particles, such as rust, are then removed by filtration, which is typically activated carbon, manganese dioxide, or other media such as filter sand.

Ozone is much faster at killing bacteria and oxidizing iron and manganese compared to chlorine or peroxide. One advantage for home use is that ozone is quite unstable and will degrade over a time frame ranging from a few seconds to 30 minutes.

So if ozone water treatment is so great, why doesn't everyone use it, you may ask?

Ozone water treatment is quite expensive compared to chlorination. It costs much more upfront than aeration, chlorine injection, or hydrogen peroxide injection! That is the primary disadvantage. Shop our ozone systems.

Ozone for Disinfection

Ozone can disinfect water of bacteria and viruses more than chlorination. To properly disinfect water with chlorine or ozone, there must be enough residual chlorine or ozone in mg/L (the same as parts per million or PPM) in the water AND enough minutes of contact time for disinfection to occur.

Water chemistry is also very important. The pH of the water (how acidic or alkaline it is), along with turbidity and other contaminants, all play a role in how effective chlorine or ozone is at disinfecting your well water of bacteria.

Ozone kills bacteria and oxidizes iron and manganese faster than chlorine or peroxide. For example, the CT value (Concentration of the oxidizer multiplied by the Time in minutes) for disinfecting water of viruses is 6. 6 minutes at 1 PPM chlorine concentration. For ozone, the CT value is less than 1 (1 PPM with 1 minute of contact time), so disinfection and oxidation occur faster than with chlorine or peroxide.

Of course, this varies depending on the water temperature and pH, but it illustrates well that ozone works faster, which saves time and money on the size of the contact tank and equipment needed to do the job.

Ozone oxides the iron, manganese, and sulfur in the water to form insoluble metal oxides or elemental sulfur. These insoluble particles are then removed by post‐filtration, typically activated carbon, manganese dioxide, or other filter media.

Ozone is quite unstable and will degrade over a time frame ranging from a few seconds to 30 minutes. It is produced on-site automatically. The rate of how fast it will degrade is a function of water chemistry, pH, and water temperature.

Bubbling Ozone Gas Into the Water Versus Injection by Venturi Under Pressure?

Ozone is a gas, so how is it transferred into water, which is a liquid?

Ozone has been used to treat water since the 1890s. During the first 75 years or so, the most common way to ozonate water was to bubble it into a column of water. This usually meant it was bubbled into the bottom of a tall (20 to 30 feet high) non‐pressurized water column through a bubbler diffuser ceramic stone or pipes with holes drilled into

Many studies have shown that the mass transfer of ozone into a column or tank of water 20 feet high or shorter is no more than 10% in a 20-foot or shorter water column. This means that 90% of the ozone produced is wasted and must be vented off.

Ozone bubbler systems are now common in well water storage tanks, and one can smell the ozone gas around these types of storage tank bubblers. One may think, “The ozone is working great! I can smell it!” but this is actually a sign of a poor design.

To get proper disinfection and oxidation with ozone, use a venturi to suck in the ozone gas under pressure into a contact tank, preferably at or around 30 – 50 PSI.

For more detailed information on various drinking water treatment methods, including the use of ozone, visit the EPA's overview of drinking water treatment technologies.

Do you have a question about ozone for your application? Fill out our Fast Help form or call us for more information!

Frequently Asked Questions (FAQs)

1. What does ozone do in well water treatment?

Ozone acts as a powerful oxidizer and disinfectant, helping to remove bacteria, viruses, iron, manganese, and sulfur odors from well water with proper filtration.

2. Is ozone water treatment safe?

Yes. Ozone is generated on-site and breaks down quickly into oxygen, leaving no harmful chemical residues behind. When used correctly, it’s safe for household water systems.

3. Does ozone remove sulfur smells from water?

Absolutely. Ozone is highly effective at oxidizing hydrogen sulfide gas (H₂S), which causes the rotten-egg odor in well water, especially when paired with catalytic carbon filtration.

4. How does ozone compare to chlorine?

Ozone works faster than chlorine, requires less contact time, and doesn’t leave a chemical taste. However, ozone systems cost more upfront and don’t leave a residual disinfectant in the water.

5. Can ozone remove iron and manganese from well water?

Yes. Ozone oxidizes dissolved iron and manganese into solid particles that can be easily filtered out using media like manganese dioxide or catalytic carbon.

6. What kind of maintenance do ozone systems need?

For optimal performance, ozone generators typically require routine cleaning, air dryer cartridge replacement, and periodic inspections of tubing, injectors, and filters.

7. Do I need a contact tank for ozone to work?

Yes, for maximum efficiency. Injecting ozone under pressure into a contact tank allows for better gas transfer and sufficient reaction time for disinfection and oxidation.

8. Can ozone kill bacteria in well water?

Yes. Ozone is a fast-acting disinfectant that quickly kills most bacteria and viruses, making it an excellent alternative to chlorine, especially in systems without chemical residuals.

9. Why do some ozone systems smell like ozone gas?

If you can smell ozone around the system, it’s likely inefficiently transferring ozone into the water (common with bubbler-style systems). Properly designed systems inject ozone under pressure to reduce waste and odor.

10. Is ozone treatment worth the cost?

While ozone systems have a higher upfront cost than chlorination or aeration, they provide chemical-free treatment, faster disinfection, and improved water quality—making them a smart long-term investment for many well owners.