The Top 5 Problems that Hypochlorite Skid-Mounted Chlorination Systems Solve

Chlorination Systems Solve

A self-contained hypochlorite skid-mounted chlorination system injecting sodium hypochlorite (NaOCl) can solve (at least) 5 major problems afflicting many small commercial, industrial or community water systems.

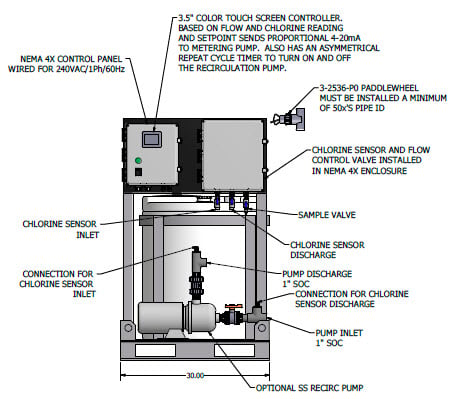

Hypochlorite Skid-Mounted Chlorination Systems, or Hypo Skids, as the name implies, are skid-mounted automatic chlorination systems that monitor flow rate and chlorine residuals and inject hypochlorite (liquid chlorine bleach) at a precise dosage. These systems are designed to meet customers' specific needs in various industries, ensuring efficient and non-hazardous chemical solutions for water disinfection.

These systems automatically maintain chlorine residuals in storage tanks, small distribution systems, and a multitude of commercial and industrial applications. They are adaptable to different industries, including municipal wastewater treatment, industrial processes, and specific operations such as oil and gas.

As more systems are installed across various industries, the recognition of a need for improved safety and efficiency has motivated advancements in equipment design and functionality.

Introduction to Water Disinfection

Water disinfection is a crucial process that removes contaminants and microorganisms from water to make it safe for human consumption. One of the most common methods is chlorination, which involves using chlorine or chlorine-based compounds to kill bacteria, viruses, and other microorganisms.

Chlorination systems are widely used in industrial and commercial applications, including wastewater treatment, drinking water distribution systems, and potable water treatment. These systems typically use chlorine gas, sodium hypochlorite, or calcium hypochlorite to disinfect water and maintain a safe level of chlorine residuals. By effectively eliminating harmful pathogens, chlorination ensures that water is safe for various uses, from industrial processes to everyday drinking water.

Benefits of Chlorination Systems

Chlorination systems offer several benefits, including effectively removing microorganisms and contaminants from water, making it safe for human consumption. These systems are also cost-effective and require minimal maintenance, making them a popular choice for industrial and commercial applications.

Additionally, chlorination systems can be used to produce sodium hypochlorite on-site, eliminating the need for storage and handling of liquid chlorine. This makes them a safer alternative to traditional gas chlorination systems.

Furthermore, chlorination systems can be designed to operate automatically, reducing the need for operator intervention and minimizing the risk of accidents. Overall, the benefits of chlorination systems make them an essential component of water treatment and disinfection processes, ensuring clean and safe water with minimal effort and cost.

These are the problems solved by the Hypochlorite Skid-Mounted Chlorination Systems:

Problem #1: Lack of chlorine residual in storage tanks

Water storage tanks that are not used regularly or sit for long periods with little water use can develop dangerously low chlorine residuals.

The Hypo-Skid measures chlorine residuals inside the storage tank, and the automatic circulation pump brings water through the tank. If the chlorine residual drops below a preset low level, fresh chlorine solution is injected until the residual is restored.

Problem #2: Varying flow rates in the pipeline or distribution system make maintaining an accurate chlorine residual difficult.

Some small community and industrial applications have several water sources feeding into a central storage tank or facility. The flow rates from different sources can vary, with the water flowing slower or faster through the piping.

The Hypo Skid easily solves this problem by sensing flow and chlorine residual and injecting chlorine proportionally, based on varying flow rates. The result is an even and consistent chlorine residual.

Problem #3: Small community systems or remote sites lack on-site staff that can operate and maintain a chlorination system, resulting in poor data collection and maintenance records.

The Hypo-Skid solves this problem because it is fully automatic and collects, stores, and/or transmits data automatically. The onboard sensor and data logger track free chlorine residuals and allow operators easy access so they can see chlorine residual levels over time.

Internet and network access make it easy to monitor the system remotely using a web browser or to tie into an existing SCADA network.

Problem #4: Gas chlorination can be dangerous and costly to operate.

Problem #5: Chlorination systems often need to be deployed rapidly, with a minimum of installation and wiring done on site if possible, but many chlorination systems require extensive wiring and set-up.

More features of the chlorination system:

Hypo-Skid chlorination systems install quickly and are up and running quickly compared to many commercial chlorination systems. Electricity plays a crucial role in the operation of these systems, converting saltwater into disinfectants like sodium hypochlorite and chlorine gas.

Electrical connections are prewired. Connect piping to and from the storage tank and program unit, and it will begin to monitor and control chlorine residuals automatically. Proper maintenance of the electrodes within the electrolytic cells is essential to prevent scale formation and ensure efficient operation.

Additionally, a water softener is an important component of the system, aiding in sodium hypochlorite production.

Safety Concerns and Storage

The storage and handling of chlorine-based compounds, such as sodium hypochlorite and chlorine gas, require careful attention to safety concerns. If not handled properly, these compounds can be hazardous, posing risks to human health and the environment.

Therefore, proper safety protocols, including the use of protective equipment and ventilation systems, must be followed when storing and handling these compounds.

Additionally, storage tanks and containers should be designed and constructed to prevent leaks and spills and should be regularly inspected and maintained to ensure their integrity. By taking these precautions, the risks associated with storing and handling chlorine-based compounds can be minimized, ensuring the safety of operators and the environment.

Additional Features Include:

Hypo Skids can be used as in-line chlorination to inject directly into distribution systems.

Can be connected to a generator and used in emergencies where rapidly-deployed disinfection is required.

Use with liquid chlorine bleach OR powdered calcium hypochlorite with water added.

Environmental Impact

The environmental impact of chlorination systems is a significant concern, as the release of chlorine-based compounds into the environment can negatively affect aquatic life and ecosystems.

However, modern chlorination systems are designed to minimize their environmental impact and can be equipped with features such as scrubbers and neutralization systems to reduce the release of chlorine-based compounds into the environment. Additionally, the use of on-site hypochlorite generation systems can reduce the need for transportation and storage of chlorine-based compounds, further minimizing their environmental impact.

Overall, the environmental impact of chlorination systems can be mitigated through proper design, operation, and maintenance procedures, ensuring that water disinfection processes are both effective and environmentally responsible.

Cost-Effectiveness

Chlorination systems are a cost-effective solution for water disinfection, as they can be designed to operate automatically and require minimal maintenance. Additionally, using on-site hypochlorite generation systems can reduce the need for storage and handling of liquid chlorine, which can result in significant cost savings.

Furthermore, chlorination systems can be designed to produce sodium hypochlorite at a concentration that is optimal for the specific application, reducing waste and minimizing the amount of chemical required.

Overall, chlorination systems' cost-effectiveness makes them a popular choice for industrial and commercial applications. They can help reduce the overall cost of water treatment and disinfection processes, ensuring safe and clean water at a lower cost.

Specifications Include:

- Heavy-duty prewired skid mounted package with carbon steel 2-coat epoxy paint.

- Heavy-duty NSF-certified electronic metering pump and sensors

- Stainless steel pump with Viton seals for recirculation systems

- A built-in timer controls pump cycles and can be wired to float switches or flow switches.

- Recirculation/Booster pump available in 20 – 200 GPM flow rates.

- The chlorine analyzer monitors the chlorine residual and automatically activates the chlorine pump to maintain accurate residuals.

- Based on the flow and chlorine reading, the 5” color touch screen controller sends a proportional 4-20Ma signal to the metering pump.

- The dual-containment chlorine solution tank holds 35 – 50 gallons of solution, which can be pumped from chlorine carboys if desired.

- An optional data logger and network interface maintain residual logs and transmit data to the network.

- Injects sodium hypochlorite, hydrogen peroxide, or sodium hydroxide for pH adjustment and other chemicals as required.

- Compact package ready to ship worldwide.

- Weather-tight enclosure options are available.

Check out the system here.

You can also download the PDF guide here.

Clean Water Systems & Stores Inc. was chosen to design and supply an advanced automated chlorine disinfection skid for a potable water storage tank at the Opal Gas Processing Plant in Lincoln County, Wyoming. You can read the story here.

Have a Question or need more information? Contact us at 831-462-8500 or email support@cleanwaterstore.com.