Adding Filter Media to Upflow Neutralizers

How to Add Filter Media to an Upflow Neutralizer

Yesterday, we described how to add filter media to a back-washing calcite neutralizer, with or without a top fill plug. Today, we’ll explain how to replace filter media in an acid neutralizer upflow system, with or without a top fill plug. First, let’s look at the differences between upflow and downflow neutralizers.

In a standard downflow neutralizer, water enters the top of the tank, flows down through the media, and backs up the distributor tube. The downflow-type neutralizer removes sediment and can be backwashed, cleaned, and re-classified, thus preventing channeling.

During backwash, the water flow is reversed. Water flows down the distributor tube and up through the media, lifting and expanding the calcite media. The water's action cleans the calcite

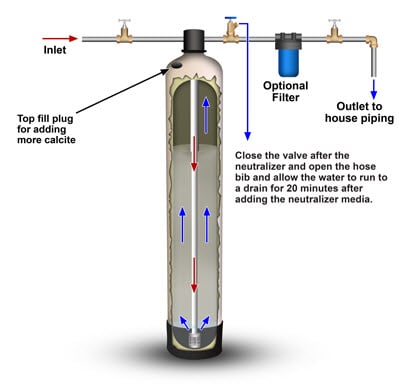

In an upflow neutralizer, the water always flows down the distributor tube and up through the calcite media.

Upflow neutralizers have no backwash control valve and are not backwashed because water is always flowing up through the calcite—as such, there is no need for a backwash.

This type works well in some applications and prevents the need for any backwash drain connection. However, the upflow types often have problems with channeling, wherein the calcite media partially solidifies, channeling water around the filter media and reducing the filter’s effectiveness.

Calcite media in these systems need to be replenished periodically to maintain effectiveness.

A bypass valve is essential for the neutralizer system's easy connection and operation. It allows for optimal system performance during setup and when adjustments are necessary.

Now, as for adding calcite media to an upflow neutralizer:

Adding Calcite to Up-Flow Type Neutralizers with or Without a Top Fill Plug

- Begin by putting the neutralizer filter on bypass or turning the water pressure off before the Neutralizer. Then, open the faucet or hose bib downstream of the neutralizer to release pressure in the tank.

- Unscrew the media fill plug with channel locks or pliers and siphon 2 to 3 gallons of water out of the filter tank using a tube or hose. If you don’t siphon the water out, when you add filter media, water will flow out the fill plug hole and onto the floor. If water on the floor is OK, you do not have to siphon water before pouring calcite media into the top fill plug hole.

- If there is no top fill plug, unscrew the top tank manifold to access the tank.

- Place a cap or wrap tape over the distributor tube, and add neutralizer filter media until the tank is 2/3 full. Do not over-fill: Be sure to leave at least 12″ of free space above the media to allow room for the media to expand during a backwash.

- Remove the distributor tube cap and reinstall the top fill plug or tank manifold. Close the valve after the upflow neutralizer so no water can flow to the house. Open the hose bib after the neutralizer and slowly turn on the water to the Neutralizer. Allow the water to run slowly at first for 10 minutes, then turn on the water to full force and rinse the media thoroughly for 20 minutes before putting it into service, if possible.

Understanding Acid Neutralizers

Acid neutralizers are essential water treatment systems designed to neutralize acidic water by raising its pH level. They utilize naturally occurring minerals, such as calcite, to correct the pH of acidic waters. This process is crucial for protecting plumbing systems, appliances, and overall water quality from the corrosive effects of acidic water. Water with a pH of less than 7 is considered acidic and can cause corrosion damage. These systems help prevent corrosion damage by neutralizing acidic water and maintaining balanced water chemistry.

Acid neutralizers, including calcite and neutralizing filters, are widely used in residential and commercial applications. Calcite filters function as acid neutralizers for water with low pH levels, effectively raising the acidity of water while introducing beneficial minerals like calcium and magnesium. Neutralizing filters often use calcite as a key component, protect plumbing systems, and maintain water quality. They provide a reliable solution for maintaining a noncorrosive equilibrium in typical plumbing systems. Additionally, acid neutralizers can be used in conjunction with other water treatment systems, such as water softeners, to offer a comprehensive approach to water treatment. This combination ensures that your water is neutralized and softened, providing optimal water quality for your home or business.

How Upflow Neutralizers Work with Calcite Media

Upflow neutralizers operate by slowly dissolving calcite media in acidic water, which in turn increases the water’s pH level. This process involves the water flowing down the distributor tube and up through the calcite bed. As the acidic water flows through the calcite bed, the calcium carbonate dissolves, releasing calcium and magnesium ions that neutralize the acidity. This interaction results in a noncorrosive equilibrium, making the water safe for typical plumbing systems.

The role of upflow calcite in maintaining a noncorrosive equilibrium is crucial. It ensures the water's pH is raised without overcorrection, preventing metal leaching from plumbing.

One of the benefits of using calcite media is its self-limiting property, which prevents over-correction of the pH level. However, it’s important to note that this process can increase water hardness. To ensure continuous effectiveness, the calcite media must be periodically replenished. Upflow neutralizers also help reduce the potential leaching of copper from plumbing systems, further protecting your pipes and fixtures. Overall, neutralizing acidic water with calcite is a natural and effective way to maintain balanced water chemistry.

Benefits of Using a Calcite Neutralizer

Using a calcite neutralizer offers several important advantages for residential and commercial water treatment systems.

Key benefits include:

- Effective pH Neutralization: Calcite neutralizers raise the pH of acidic water, making it safe for consumption and preventing corrosion in plumbing systems.

- Protection of Plumbing: By neutralizing acidity, these systems help prevent corrosion in pipes, fittings, and appliances, extending their lifespan and reducing costly repairs.

- Reduced Heavy Metal Leaching: Neutralizing acidic water helps prevent the leaching of heavy metals like copper and lead into your water supply, ensuring safer drinking water.

- Improved Water Quality: Neutralizers enhance the taste, odor, and overall quality of water, making it better for drinking, cooking, and other household uses.

- Cost-Effective Solution: Addressing acidic water with a neutralizer saves money over time by minimizing the need for frequent plumbing repairs and replacements.

- Environmentally Friendly: Calcite neutralizers use naturally occurring calcium carbonate, offering an eco-friendly, sustainable water treatment option.

- Low Maintenance: These systems require minimal upkeep, typically needing only periodic replenishment of the calcite media to maintain performance.

Choosing the Right Neutralizer System

Selecting the right system is essential for effective pH neutralization and optimal performance.

When choosing a neutralizer, consider the following factors:

- Water pH Level: Test your water to determine its pH. Choosing a system designed for your specific pH range ensures better results.

- Water Flow Rate: Make sure the system can handle your household or building's water flow rate to maintain consistent performance.

- Calcite Media Quality: Use high-quality media designed for your treatment needs for the most effective pH adjustment.

- Additional Features: Some systems offer enhancements like bypass valves or automatic controls, which can make maintenance easier.

- NSF Certification: Look for systems that are NSF-certified to guarantee safety and effectiveness.

- Expert Consultation: If you’re unsure which system to choose, consult a water treatment professional for tailored advice based on your water quality.

Adding Calcite to Your Water Treatment System

Adding calcite is a simple but important maintenance step that keeps your system working properly.

Here’s how to do it:

- Determine the Amount Needed: Calculate the right quantity of calcite based on your system’s size, flow rate, and water pH.

- Choose the Right Media: Always select high-quality calcite media suited for your water treatment system.

- Install the Calcite Media: Follow the manufacturer's instructions carefully to ensure proper loading and system setup.

- Monitor Water pH: Regularly check your water’s pH levels to verify that the calcite is working effectively.

- Replenish as Needed: Top off or replace the calcite media periodically to maintain optimal pH control.

Factors Affecting Neutralizer Performance

Several conditions can influence how well your neutralizer performs.

Key factors include:

- Water Flow Rate: High flow rates can reduce the contact time needed for effective pH adjustment. Make sure your system is sized correctly.

- Water pH Level: Extremely low pH levels may require additional treatment steps or specialized media to achieve the desired neutralization.

- Calcite Media Quality: Poor-quality calcite can lead to inconsistent results or require more frequent replenishment.

- Maintenance Practices: Regular monitoring, media replenishment, and system checks are crucial for maintaining consistent performance.

- Water Chemistry: Factors like hardness, alkalinity, and other minerals in your water can impact the neutralizer’s effectiveness. Testing your water chemistry can help you optimize system performance.

Troubleshooting Common Issues

Common issues with calcite neutralizers include clogging, reduced flow rates, and ineffective neutralization. Clogging can occur due to excessive sediment or debris in the water, which can be resolved by cleaning or replacing the calcite media. Reduced flow rates might be caused by a blockage in the system, which can be addressed by checking and clearing the blockage. Using corosex media in blends with calcite can improve performance by allowing for higher service flow rates.

However, it is important to note that Corosex media is not self-limiting and may over-correct the pH, potentially leading to excessively high pH levels, especially at low flow rates.

Ineffective neutralization can result from various factors, including incorrect calcite media, inadequate flow rates, or excessive water acidity. To troubleshoot these issues, it is essential to regularly monitor the water's pH levels and flow rates. Adjusting the service flow and service flow rates as needed can help maintain optimal performance. Regular maintenance and upkeep are crucial in preventing common issues and ensuring the system operates effectively.